Taig Lathe – Bodine Motor Mount

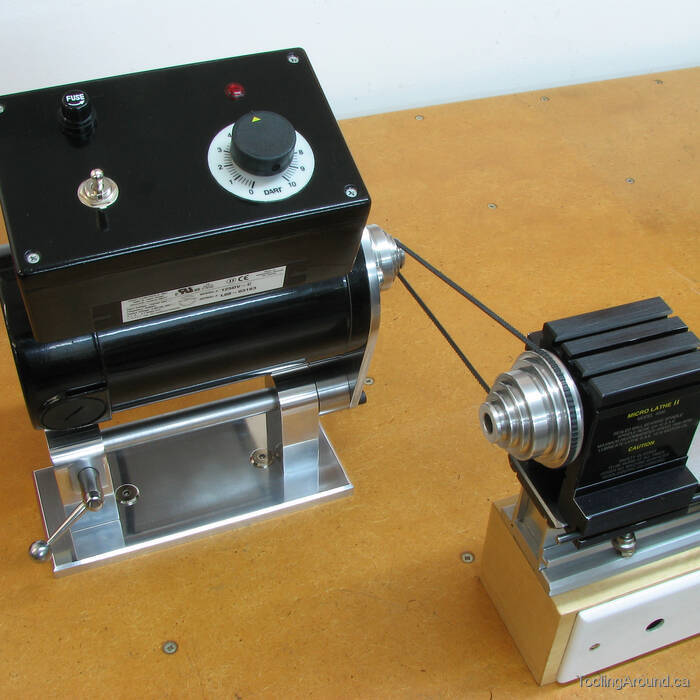

It happened like this. I started with a very old 1/4HP AC motor. It worked fine, especially after I replaced its bearings, but it was pretty big; the motor mount I built was not one of my better ideas; and I knew that a variable speed motor would be better. My wife gave me a Sherline motor and controller as a Christmas gift and I adapted it to the Taig lathe. It was a wonderful match. However, I later became concerned about the motor on my Taig mill. It worked fine, but it was out of balance and I knew that the Sherline motor would work well there. So, when two of my enablers took me in hand to a motor repair shop in an industrial park, I was primed to purchase a very nice new Bodine DC motor (at a remarkably good price) and the parts for a controller. What you see on this page is the result.

The controller needed to be mounted in a box and that needed to be mounted on the motor. Then the motor needed to be mounted on something that would be solid enough to maintain good belt alignment and permit easy adjustment without using tools.

There are lots more pictures, so I've divided them into multiple pages:

So, how has it worked out? I've been very pleased with the result. The only remaining change to make is to replace the Taig pulleys with two-step pulleys. This isn't strictly necessary, as the 2M belt on the stock Taig pulleys does the job just fine. However, I want to achieve two more things. First, I would like to get lower spindle speeds while keeping the motor speed up a bit to help ensure sufficient torque. Second, the six-step pulleys certainly aren't required and a two-step pulley would hopefully expose enough of the end of the spindle to permit the attachment of some other things I've been thinking about. On balance, it's a successful modification.

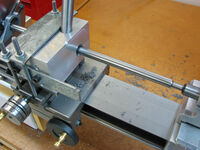

Making the Bodine Motor Mount

Click on a photo to view the associated topic.